Chemicals and textiles are deeply interwoven. Textiles go through numerous production steps from the raw material to the finished product. For example, the cotton used to produce one t-shirt is estimated to require one-third of a pound of toxic chemicals.

Both synthetic and natural fibers require a large amount of chemical processing throughout the garment manufacturing process as well as through the life cycle of a garment. This includes establishing garment performance and function, such as water resistance and stretch, as well as design, including coloring, dying and printing.

Twenty years ago, most companies didn’t have any idea of what was in their products unless there was a legal requirement. Although chemicals remain largely invisible and unnoticed in the final product, many chemicals pose a risk to the health of the employees who work in close proximity to the chemicals, the consumers who wear the garments on or near their skin, and the environment.

The environment is especially at risk because chemicals are an integral part of millions of manufacturing processes throughout a supply chain, increasing the risk of chemical release through air, vapor, or wastewater, all of which enters the ecosystem.

The number of suppliers involved throughout the supply chain has rapidly increased in the past 20 years. For brands, this has resulted in a complex, interlocked system with a low degree of oversight and control. Chemical compositions to improve garment performance and functionality, or to replace a chemical determined to be hazardous, are developing rapidly. Brands struggle to maintain abreast to the continuously updating legislation and regulation, aimed at consumer safety.

Incorporating chemical change management throughout the textile supply chain is a primary driver to establish responsible and safe chemical management. Chemical management is important in order to understand what is being put into the supply chain stream. A primary part of effectively managing and producing safe apparel is being able to prevent harmful chemicals from entering the process stream right from the start.

THE BEGINNING

The importance of chemical management begins before any processing takes place. The very first step is selection and purchasing of chemicals. By selecting non-hazardous and non-harmful chemicals, the level of concern can be reduced throughout the supply chain.

This is known as the input stream management approach, which means that if the chemical substances used throughout the supply chain are safe, then the end product will be safe for consumers and the workplace will be safer for employees.

The input stream management approach eliminates the need for control mechanisms for hazardous chemicals, and it works with a hazard prevention system. This is easier to establish and maintain, making it a more effective management system. The first step of responsible chemical management relies on responsible business practices in large part by the chemical suppliers who create the chemical compositions.

A responsible chemical supplier considers the ingredients in the chemical composition and, moreover, is transparent about the ingredients. Transparency is a basic necessity for chemical management. You cannot control what you don’t know.

Transparency allows buyers to make responsible purchasing decisions. If a chemical supplier is not able to be transparent about its ingredients, a buyer will not be able to be transparent upward in the supply chain, creating difficulties when a hazardous chemical is found. This communication is why transparency is critical at the very beginning of the supply chain.

Communication is necessary for employee training in factories and mills on how to handle chemicals. The next steps for proper chemical management are proper delivery and receiving of the chemicals, and proper storage of the chemicals, along with diligent maintenance and review of chemical supply. It is also important for the employees to know the right way to transfer and transport the chemicals.

The final steps are the most intensive processes for chemical use, with the largest potential for adverse impact. These steps include the actual use and processing of the chemicals in the manufacturing process, and the disposal and discharge of chemical waste and emissions after production. Most chemical impacts occur in these steps.

Waste can be classified into three types. The first is pre-consumption waste, which consists of trimmings and raw material. The second is post-consumption waste: the end of the life cycle of most garments when they are discarded by the consumer. Lastly, there is post-industrial waste, which is waste related to dyes, finishing, and processing of chemical waste.

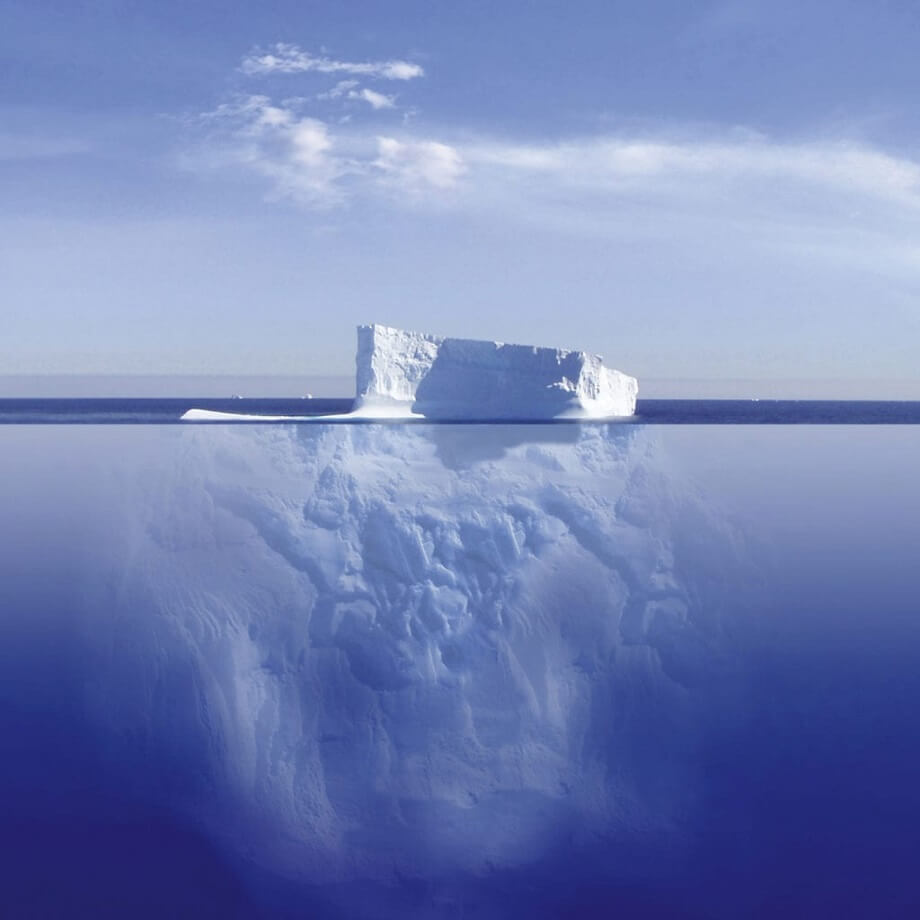

At the end of the process there is also the issue of properly disposing of empty containers, which still hold traces of chemicals. As you can see, the number of things to consider, to think about, and to implement in responsible chemical management is much larger than what meets the eye and includes the entire life cycle, not just the use and disposal of chemicals.

SO WHAT CAN COMPANIES DO?

Effective chemical management depends on establishing policies and procedures which appropriately manage chemicals throughout their life cycle. For many companies the best starting point is to set up a chemical change management system, or management of change.

Chemical change management starts with an assessment of the organization’s current situation at the plant or company in question, and preferably throughout the process life cycle, as well as company offices which are involved in the design and planning of major projects.

It is in the best interest of an organization or manufacturer who undertakes chemical change management to invite an independent external specialist to assess the existing situation. An independent specialist can bring an outside perspective of the internal situation, as well as knowledge of external factors that may influence the internal operations of an organization.

This specialized third parts can then support an organization in creating a roadmap to success.

WHY INDEPENDENT THIRD-PARTY CONSULTANTS ADD VALUE

If a proposed modification is made to a process without suitable review, the risk of an accident or improper substitution can increase significantly. Independent third parties, verifiers, or certification bodies are highly relevant for proper review and implementation throughout these complex supply chain systems.

These third parties bring credibility to an organization’s desire to be better and increase transparency and traceability, which are key focus areas that are being demanded by players along the supply chain and consumers alike. It is for this reason that Bluesign is the leading expert in the field. Using the input stream management approach, Bluesign evaluates the chemical safety from the beginning of the manufacturing process.

The bluesign® CRITERIA set contract binding guidelines for implementation into the factory or mill. These guidelines take into consideration the most stringent global regulations. Every year, the new regulations and new information on chemical compositions is revised, and the bluesign® CRITERIA is updated accordingly. With the Bluesign on-site verification process, buyers who purchase from bluesign® SYSTEM PARTNERS can conduct business with simplicity and peace of mind.

CHANGES FOR VALUE

Nothing can be accomplished without safer, cleaner, and better chemistry, because it is in everything we touch. Effective chemical change management requires the cooperation of all relevant stakeholders as a collective action. It is important that all stakeholders define specific, individual and collective goals which loop in a continuous cycle of development to factor in new information and BAT.

It is a myth that chemical change management is only for companies that previously dumped their chemical sludge into rivers. Chemical change management, led and steered by an external specialist, is a catalyst for forward-thinking and leading companies who want to maintain their leadership status.

This external specialist can not only bring unknown gaps to light, but more importantly contribute the best available techniques, leading to increased value and ROI. Companies that practice responsible chemical management are better prepared for the future, putting them ahead of the competition.

WHAT DOES THIS MEAN FOR YOU?

When brands ask, “Why can’t my supplier take care of this?” they are forgetting that they are the ones that initiate the process in the design phase. When designing a garment, there is always the question of what attributes the garment will have. It is up to the brands to have enough knowledge about the impacts of the chemical compositions for the desired attributes so that they can open the conversation with their suppliers. You need to know what questions you can ask your suppliers.

Opening the conversation not only allows the suppliers to meet your requirements, but getting to know your suppliers allows for the ability to be transparent to their end-consumers. Its everyone’s responsibility throughout the supply chain to know the impacts of the decisions that are made and to be a positive part of a bigger system. If you don’t know, you can’t care. Check out Fashinnovation Blog to learn more about how chemicals play a negative role in achieving sustainability goals!